GOLD EP / GOLD EP WHITE

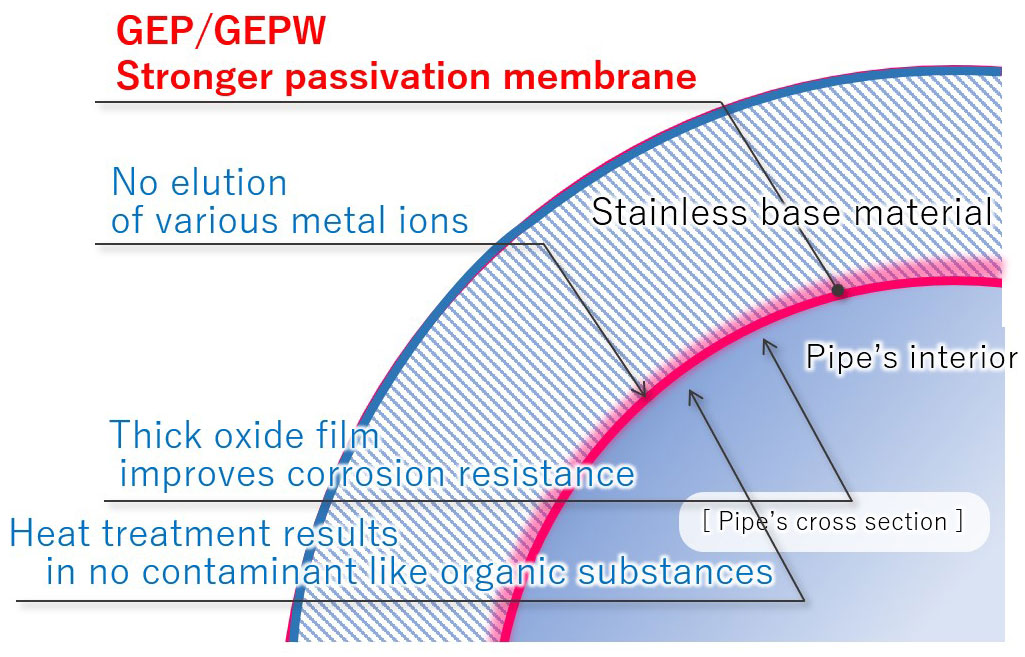

Minimize corrosion and metal elution with a higher quality passivation membrane!

*GEP/GEPW processes are generally applied only for the inside of the pipes

Thicker, more robust, more homogeneous

GOLD EP (or GEP)、GOLD EP WHITE (or GEPW) can provide all the characteristics of electrolytic polishing (EP: Electro Polishing, electrolytic polishing, electro polishing) but with higher standard.

GOLD EP / GOLD EP WHITE is a surface treatment that enhances corrosion resistance and suppresses metal elution while keeping the excellent features of stainless steel such as ease of processing and strength. These ultra-clean technologies greatly expand the applicable range of stainless steel.

Content (with links)

1. About GEP / GEPW processing

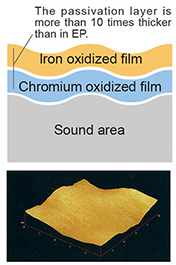

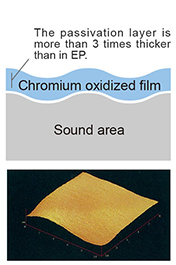

The surface treatment technologies GOLD EP (GEP) and GOLD EP WHITE (GEPW) are performed as an additional treatment after electropolishing (EP). When EP-processed stainless steel is heat-treated by GEP treatment, both the iron oxide layer on the surface and the chromium oxide layer on the lower layer increase in thickness (about 10 times that of general EP). After GEP, GEPW removes the iron oxide layer on the surface and leaves only the completed chromium oxide film.

|

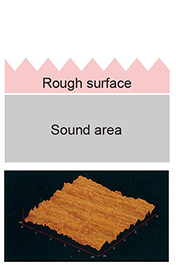

Pre-Electro polishing |

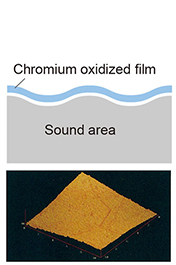

Electro polishing |

GEP Processing |

GEPW processing |

|---|---|---|---|

|

The heterogeneous oxidation state and granular particles are easy to get rid of after the surface is affected. |

Eliminate uniform oxidation state by Electropolishing. The surface becomes a flat and smooth metal surface. |

Burn the object in an oxidizing atmosphere. The passivation layer of the chromium oxide film grows and increases in thickness. Furthermore, the passivation layer of the iron oxide film covers the upper layer. |

Remove the iron oxide film from the surface with a chemical solution. The surface layer is a passive layer of a chromium oxide film that is three times as thick as a general EP.. |

|

|

|

|

|

The surface of the metal is strongly affected by physical processing such as deterioration of the crystal structure and adhesion of dirt. |

A chromium-enriched layer with excellent corrosion resistance is formed. Its thickness is about 1 to 3 nanometers. |

This surface of metal suppresses the elution of metal ions in alcohol liquid or ozone water having a large amount of residual oxygen. |

This surface of metal suppresses the elution of metal ions in ultrapure water or organic amine solution with strong corrosiveness. |

2. Features and surface structure resulted from GEP / GEPW

(1) Features

GOLD EP / GOLD EP WHITE has the following excellent features that enhance the features of general electro polishing.

-

Effective against elution of metal ions and TOC (total organic carbon) pollution

GOLD EP: Strong against elution with alcohol and ozone water with a lot of residual oxygen

GOLD EP WHITE: Strong against elution with ultrapure water and organic amine chemicals -

Resulting in a highly smooth surface which is resistant to particles like dust, contamination, etc.

-

Excellent heat resistance and pressure resistance, and has a wide range of applications

-

Excellent workability such as bending, ferrule connection, and welding.

-

Mechanical strength is equivalent to stainless steel

* TOC (Total Organic Carbon):

A typical indicator of water pollution. Water is of biological origin and is contaminated with various organic substances such as sugar, alcohol, resin and oil. The index is based on the total amount of carbon (C) contained in these organic substances.

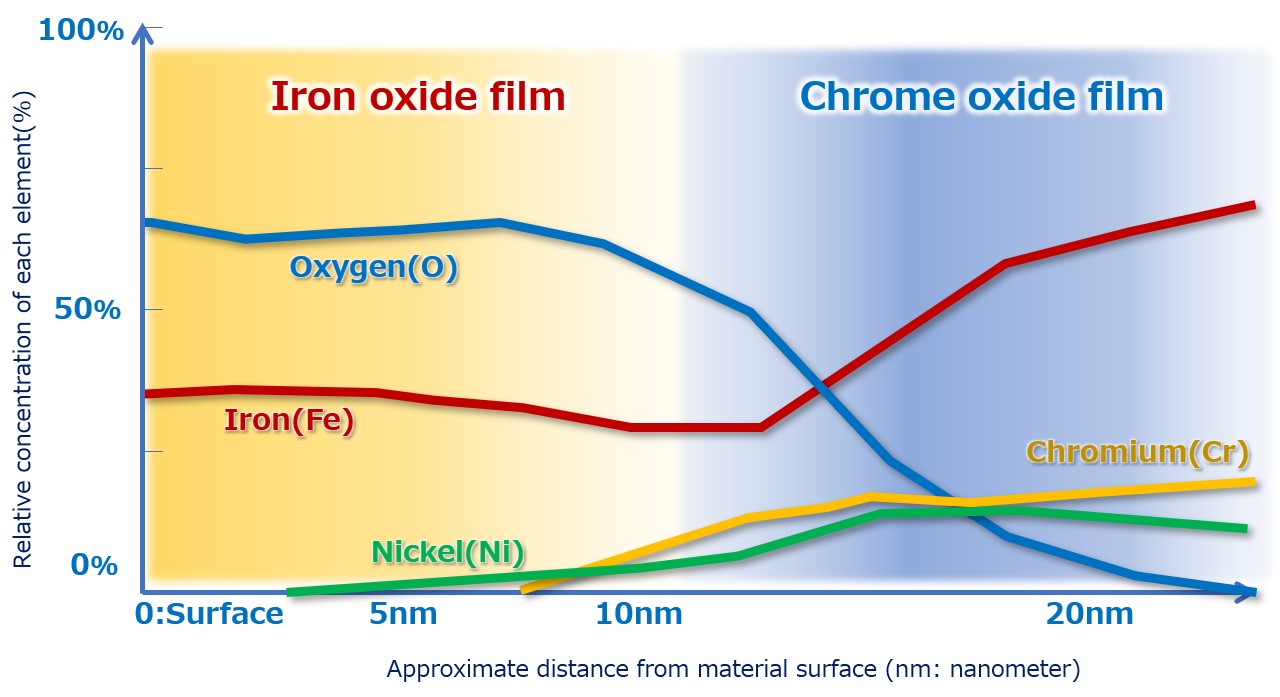

(2) Surface coating structure (GEP)

GOLD EP has the following surface structures and characteristics that are effective in improving corrosion resistance and cleanliness by applying appropriate heat treatment.

i) Amorphous ceramic structure

The metal oxide produced after heat treatment has a very strong and clean surface and an amorphous ceramic structure with little variation in surface composition.

* Since the heat applied to the metal surface after mechanical polishing is not uniform, the surface composition varies, and fragile composition parts can likely become the starting point of corrosion.

ii) Thick passivation film and chromium condensation on the surface

During surface treatment, the composition moves from the surface to a relatively deep layer and is passivated. In addition, since the chromium component is condensed in the extremely shallow surface layer, the corrosion resistance is improved.

[Graph 2-1 Rough surface composition-GEP]

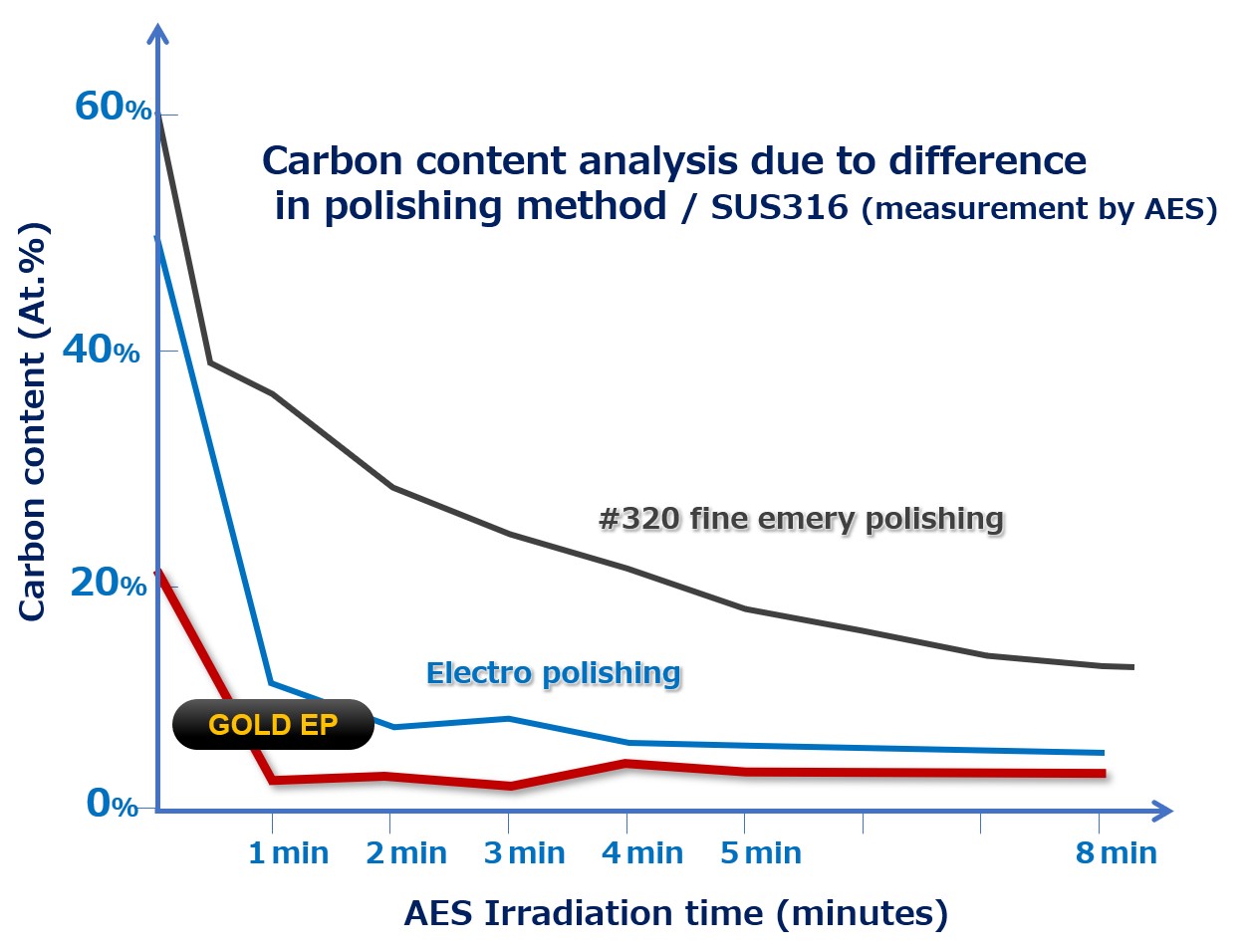

iii) The number of organic components absorbed on the surface is small

Surface contamination by organic substances is unavoidable in the passivation film formed in the atmosphere. However, with GOLD EP, it is possible to finish in a carbon-clean state with extremely few carbon compounds (organic substances) that stubbornly adsorb to the metal surface that cannot be removed by cleaning by heat treatment.

[Graph 2-2 Carbon content analysis due to difference in polishing method / SUS316 (measurement by AES)]

iv) Other impurities are rare

The finishing surface after GOLD EP is in a clean state with fewer impurity elements detected compared to other general surface treatments, even when examining trace amounts of impurities near the surface. Even a small amount of impurities may affect the physical properties of the surface.

* AES: Auger Electron Spectroscopy (AES):

A method of analyzing the elements that make up the sample surface by measuring the kinetic energy of Auger electrons that have element-specific values. The surface of the sample is irradiated with an electron beam to emit Auger electrons.

* Emery:

The mineral consisting of aluminum oxide crystals is called corundum. Granules mixed with magnetite and hematite are called emery and are used as natural abrasives.

* References on changes in iron ion elution amount: Shinko Pantech Technical Report Vol.34 No. 1 (1990/3) “Gold EP”

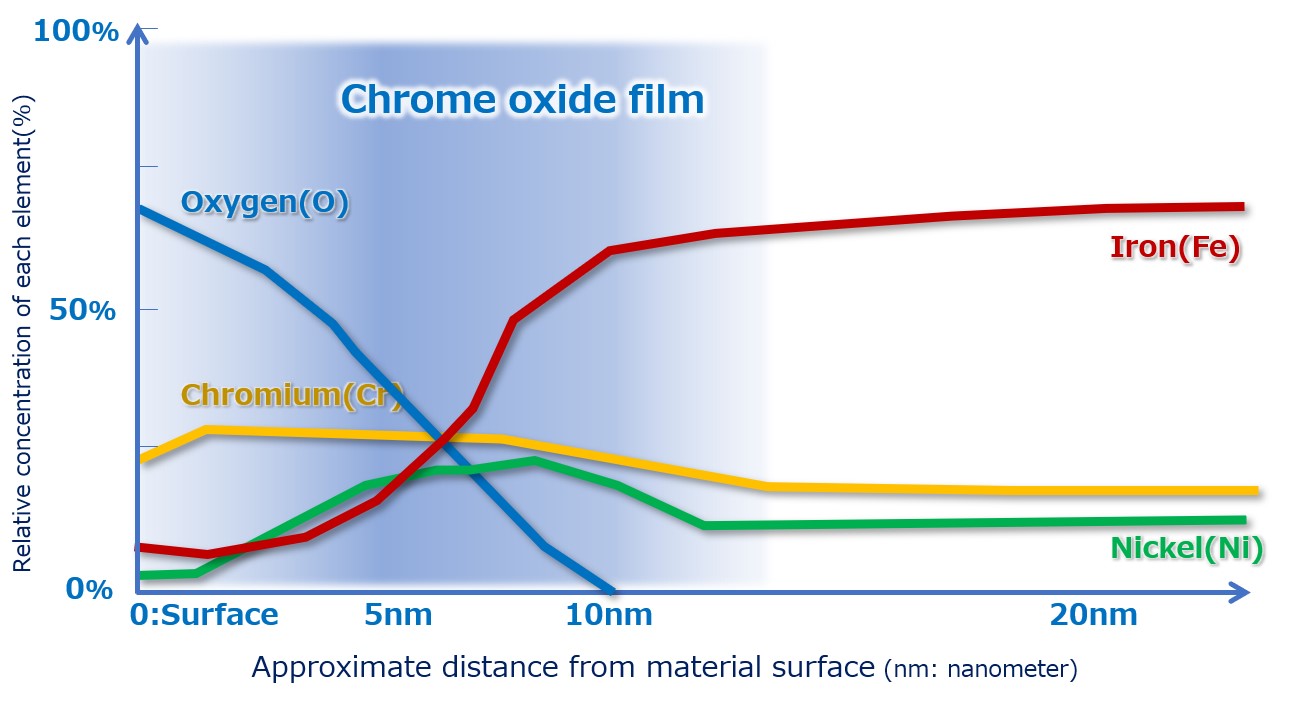

(3) Surface coating structure (GEPW)

The state of the surface composition of GOLD EP WHITE from which the iron oxide film has been removed by chemical treatment after GOLD EP treatment is as follows.

[Graph 2-3 State of rough surface composition-GEPW]

3. GEP / GEPW characteristic graph

Our actual measurement data are shown for GOLD EP (GEP), which is strong against metal elution of alcohol and ozone water with a large amount of residual oxygen, and GOLD EP WHITE, which is strong against metal elution with ultrapure water and amine-based chemicals.

(1)Features of GOLD EP (GEP)

3-1-1:

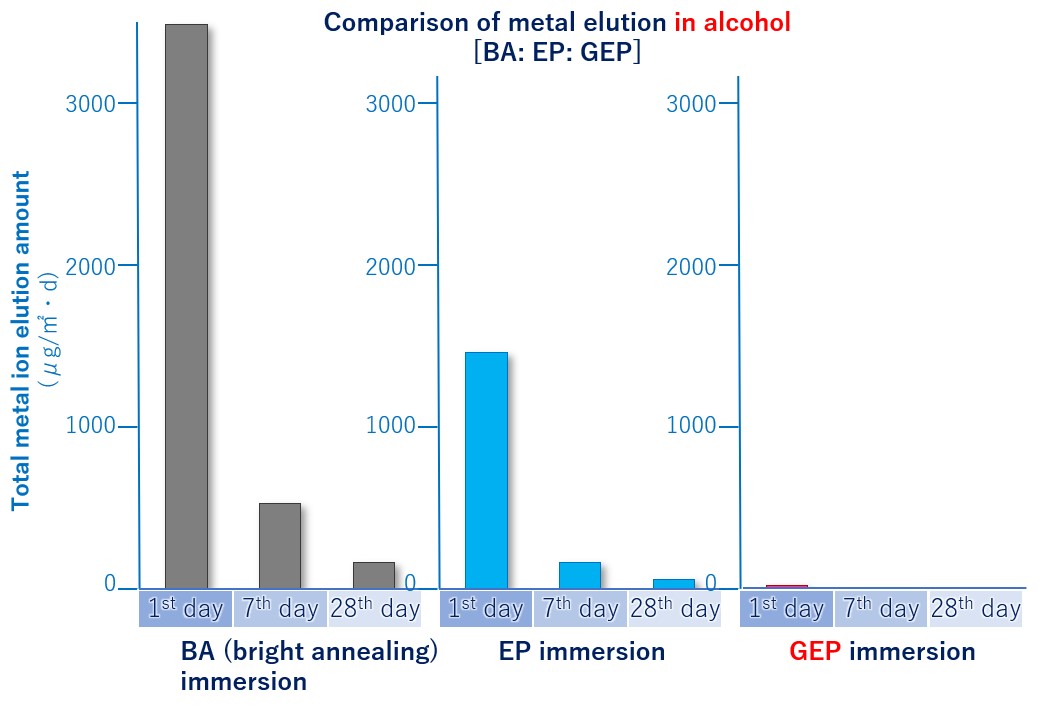

The amount of metal elution of stainless steel BA (bright annealing), general electropolishing (EP), and GOLD EP (GEP) in an alcohol solution was measured for 4 weeks.

[Graph 3-1-1: 28-day measurement of metal elution of GEP with alcohol]

3-1-2:

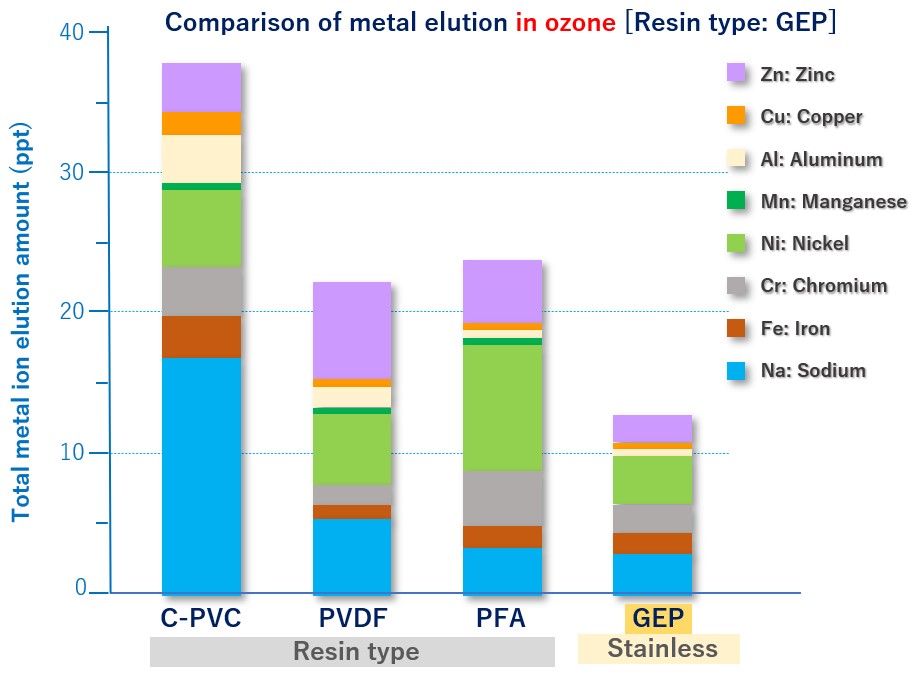

Measure the total amount of metal elution of 3 types of resin and GOLD EP (GEP).

[Graph 3-1-2: Total elution of metal ions with respect to ozone in GEP]

Resin to be compared

C-PVC : Chlorinated PolyVinyl Chloride

PVDF : poly vinylidene fluoride

PFA : copolymer of tetrafluoroethylene (C2F4) and PerFluoroAlkoxyethylene

* Ppt: 1 trillion parts per million (reference ppm: parts per million)

3-1-3:

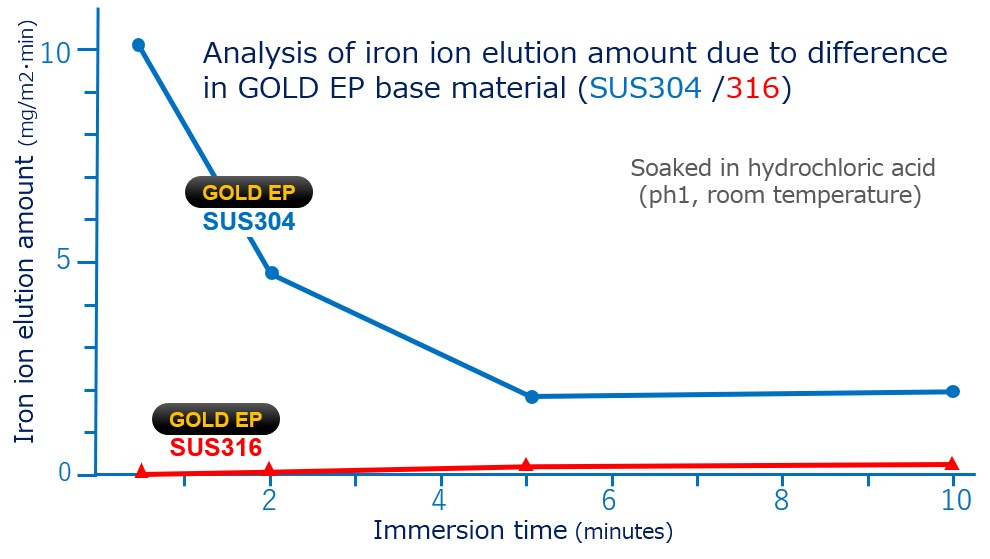

The graph which compared the metal elution amount when SUS304 and SUS316 were used as the base material of GOLD EP (GEP). (Immersed in hydrochloric acid of PH1 as an accelerated test)

Even with the same GEP, the SUS316 base is better because the elution of iron ions is suppressed more stably.

[Graph 3-1-3 Difference in metal elution amount resulted from different GEP base material]

3-1-4:

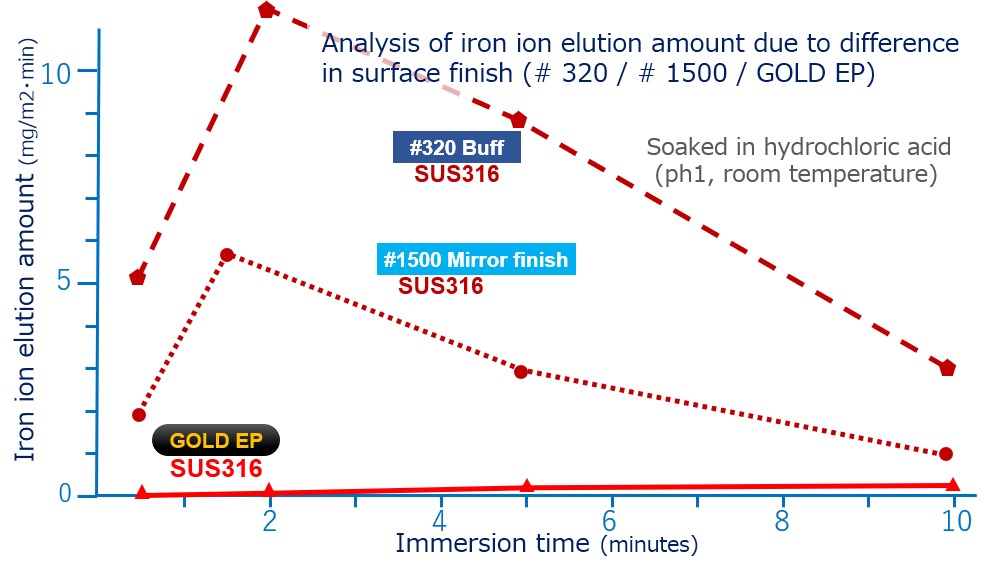

A graph comparing the amount of metal elution after applying three types of surface treatment (# 320 buffing / # 1500 mirror finish / GOLD EP) to SUS316. (Immersed in hydrochloric acid of PH1 as an accelerated test)

Even with the same SUS316, the elution of iron ions is significantly suppressed in the GEP-treated material.

[Graph 3-1-4 Difference in metal elution amount due to surface treatment of SUS316]

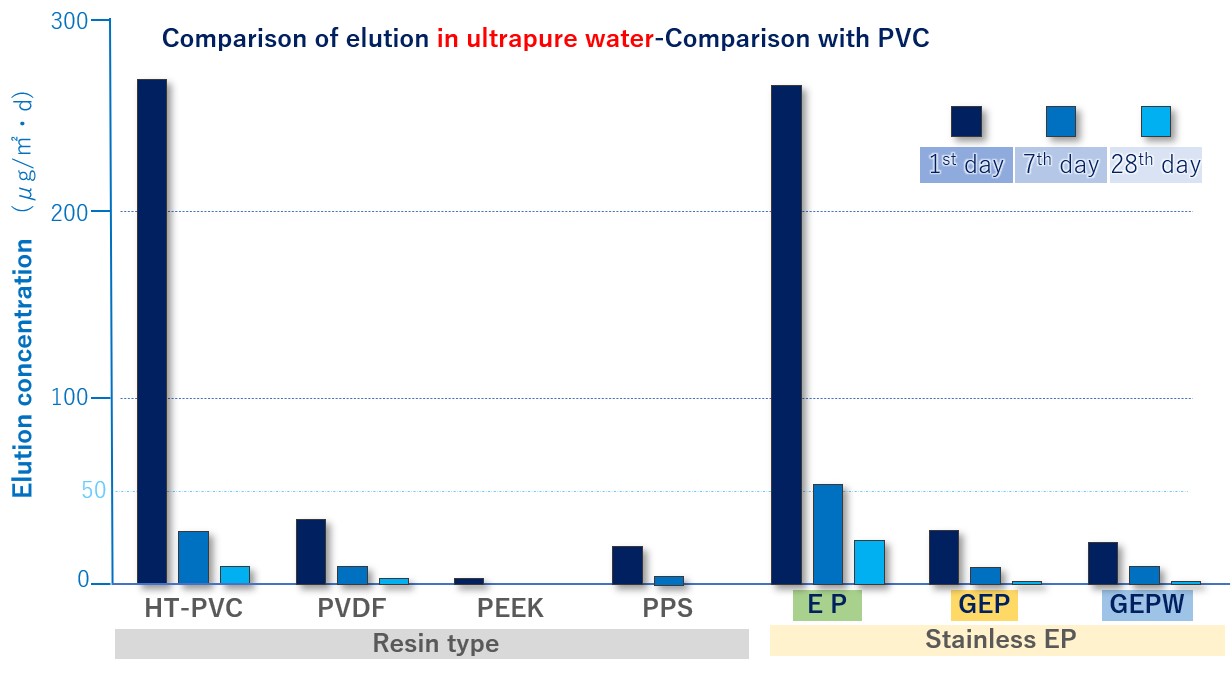

(2) Features of GOLD EP WHITE (GEPW)

3-2-1:

Results of a 4-week comparison of the initial elution of four types of resin used for piping materials and each grade of stainless electropolishing with ultrapure water.

[Graph 3-2-1: Measurement of GEPW metal elution in ultrapure water for 28 days]

PVC resin to be compared

HT-PVC : (thermal resistance)poly vinyl chloride

PVDF : poly vinylidene fluoride

PEEK : polyetheretherketone

PPS : poly phenylene sulfone

Corrosiveness due to ultrapure water:

We may also perform cleaning with ultrapure water after electro polishing process for stainless steel products for sanitary use. Ultrapure water is often used for cleaning products (such as semiconductor wafers) that do not go well with fine particles, bacteria, organic substances, and metal ions. Since ultrapure water is highly corrosive, PVC-based resin piping may be used, but problems may occur such as elution from piping materials and heat resistance for sterilization.

Although GOLD EP or GOLD EP WHITE is done for stainless steel material, it has excellent corrosion resistance and elution characteristics, so the stainless steel piping material can be applied to ultrapure water piping depending on the conditions.

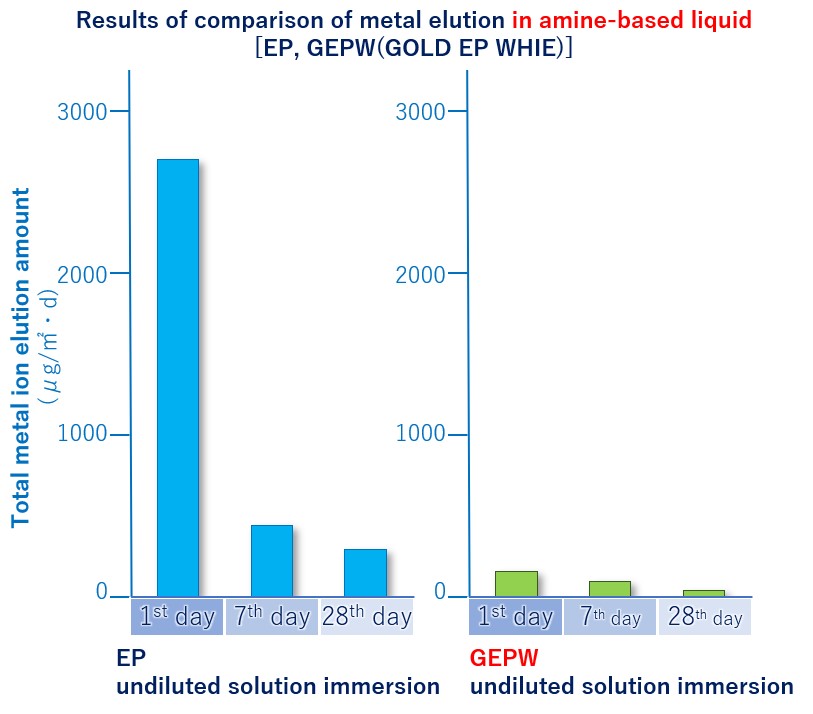

3-2-2:

Results of comparison of metal elution in amine-based liquid by general electro polishing (EP) and GOLD EP WHIE (GEPW) for 4 weeks.

[Graph 3-2-2: 28-day measurement of metal elution of GEPW in ultrapure water]

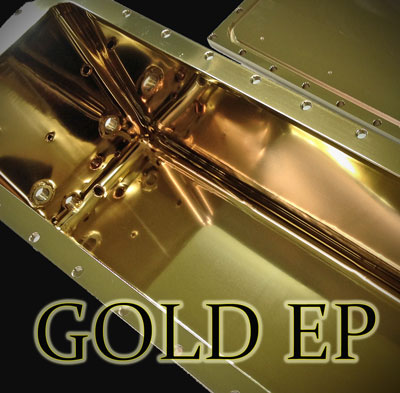

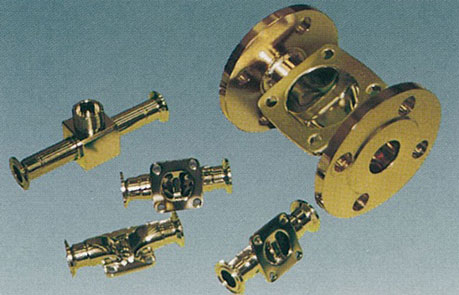

4. Samples of GEP processed product

Ozone(O3 ) changes to stable oxygen (O2 ) if left untreated. In the process of changing to oxygen, ozone can oxidize, destroy and inactivate biological components that make up bacteria and viruses. Ozone is widely used in the food manufacturing and processing fields because it can be sterilized and deodorized without heating.

Stainless steel containers and pipes are often used in food manufacturing and processing, but ozone is also known to have a very strong corrosive effect on austenitic stainless steel, so sufficient consideration must be given.

Pump

Plumbing parts

Filter housing

Ozone water valve

In sake brewing, even if just a small amount of iron ions (about several tens of ppb) is eluted, the iron ions react with sake, causing discoloration and deterioration of taste. GOLD EP can also be considered for application to filtration equipment, piping, and valves.

GEP can also be used in extremely severe process lines such as to shorten the time to reach a predetermined vacuum in a high vacuum environment, high-purity gas piping lines, and equipment that is concerned about the electrical characteristics of products due to metal elution.

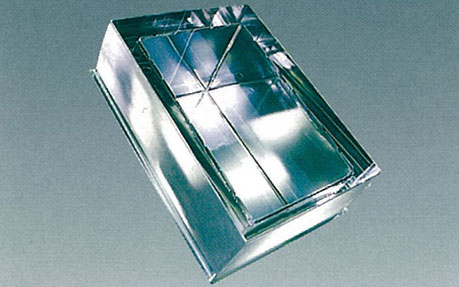

5. Samples of GEPW processed product

Amines are ammonia(NH4 ) hydrogens substituted with alkyl groups, which are naturally produced by microorganisms during putrefaction and fermentation. It is often used as a raw material for semiconductor manufacturing (dry etching) and pharmaceutical manufacturing.

Cleaning chamber

Amine-based chemical solution fittings

Washing tank

Vacuum chamber

In piping through which amines flow, the corrosion rate may increase depending on the type of amine and impurities contained in the solution, temperature and flow velocity.

6. GEP / GEPW: Other sample photos

[TEE: General Electropolishing (EP) and GOLD EP (GEP)]

[90 degree elbow: general electro polishing (EP) and GOLD EP (GEP)] [GEP sample]

Click here for details on “Electro polishing (EP)”.