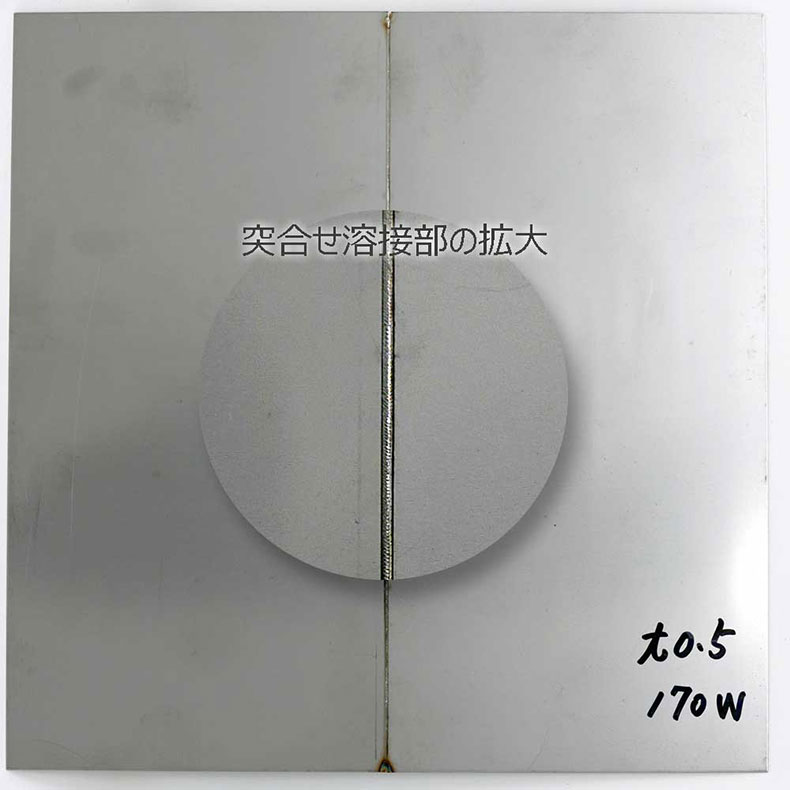

Fiber laser welding: Butt joint and T-joint welding of flat plate

Fiber laser welding emits a laser, like YAG welding, but the laser is generated in the oscillating fiber and emitted from the torch through the output fiber.

Nissho Astec installed a fiber laser welding machine in 2019. We are working to diversify the processed products that can be manufactured, improve welding accuracy, and reduce welding time.

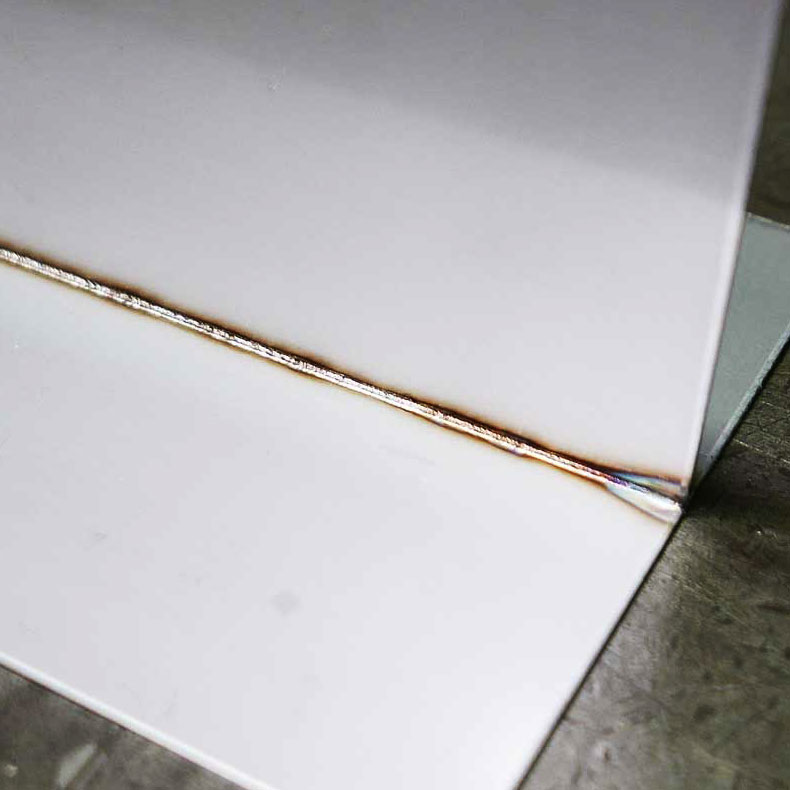

Welding with a fiber laser has a much higher concentration of laser energy than general TIG welding. As a result, the welding heat does not spread over a wide area, and the welding heat is released in a narrow and deep area. In addition, the beam quality of CW (continuous speed) oscillation is excellent, and CW seam welding can produce a more beautiful finish than YAG welding.

As for the speed of welding, he feels that “the fiber laser is done before half of the previous welds are done.

By changing the carbon tip at the end of the torch, it is possible to smoothly weld T-shaped parts such as containers.

Fiber laser welding is not only expanding the processing variations of non-piped products such as boxes and containers, but is also trying to expand its effectiveness to a wide range of applications such as SUS stainless steel piping by devising jigs.

Features of Fiber Laser Welding

1. Less likely to distort the work

2. Capable of fine and stable spot welding

3. Capable of seam welding and cutting in a short time

This is a very attractive feature compared to conventional welding.

Fiber Laser Welding Machine from AMI Co., Ltd.

Model AFL-800 (800W)