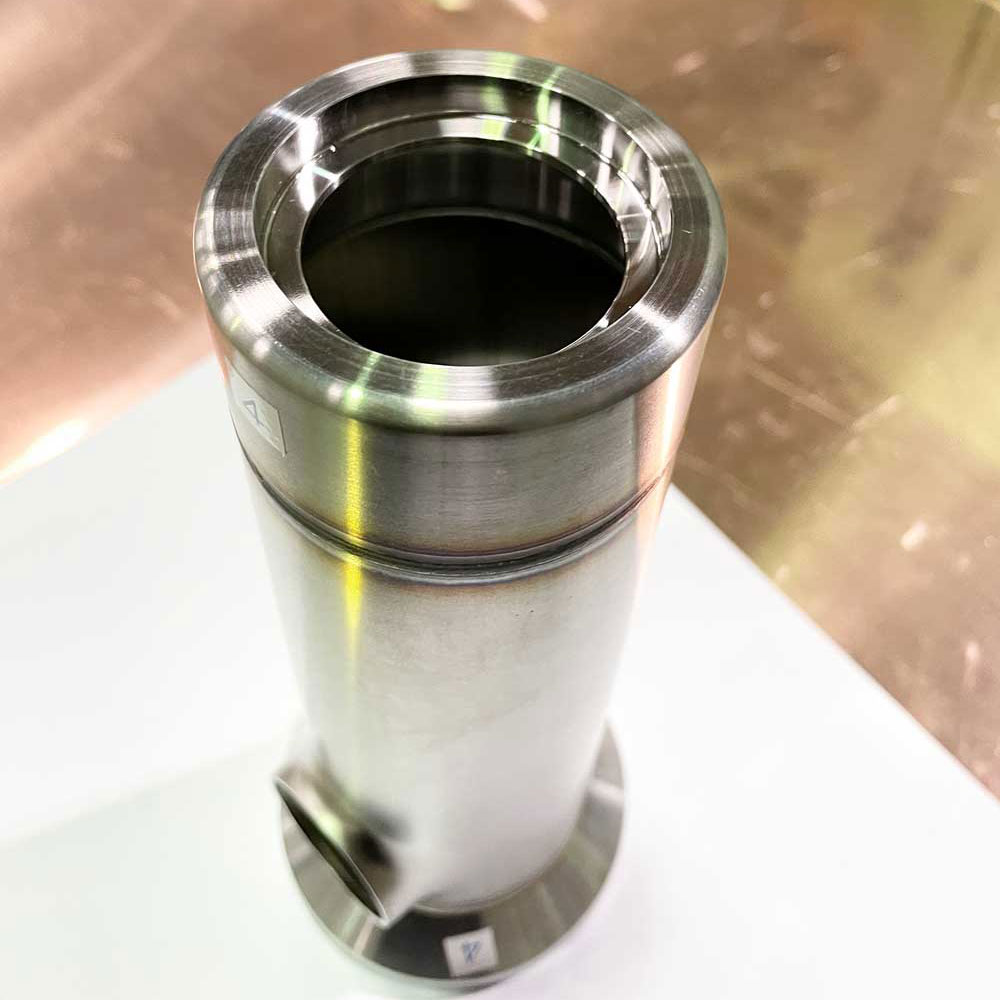

Fiber laser welding: Low-distortion production of thin cylindrical shape

The fiber laser welding machine that we are using at Meishin Factory has extremely thin laser beam, and the spread of welding heat is minimized. Those features result in the following advantages.

(1) Thermal distortion is minimized

→Suitable for thin plates that are prone to distortion

(2) Less welding burn (narrow area)

→Make the post-processing more efficient

(3) Welding speed is fast

→Reduction of work time

Since fiber laser welding makes it easy to weld plates, it is also used to process auxiliary product for process piping such as containers and tanks. This welding method is also being considered to be used for manufacturing thin-walled tanks and pipes that prefer less welding distortion and burning.

Especially in the case of thin plate welding, wasteful welding heat spreads and distortion is likely to occur in normal welding, and it may be difficult to obtain design accuracy.

However, in the case of fiber laser welding, the range in which welding heat is transmitted is limited because the beam is narrowed down very finely, which makes welding with less distortion is possible.

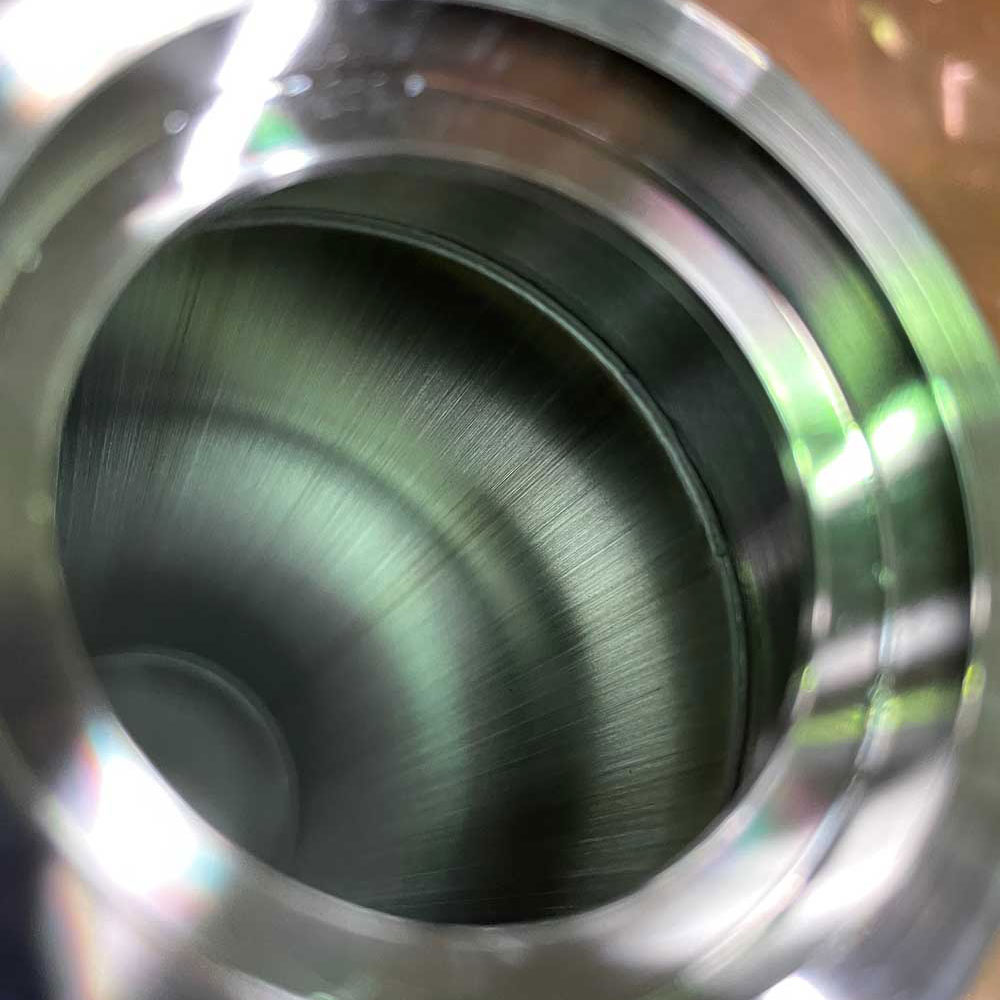

Inside the butt weld

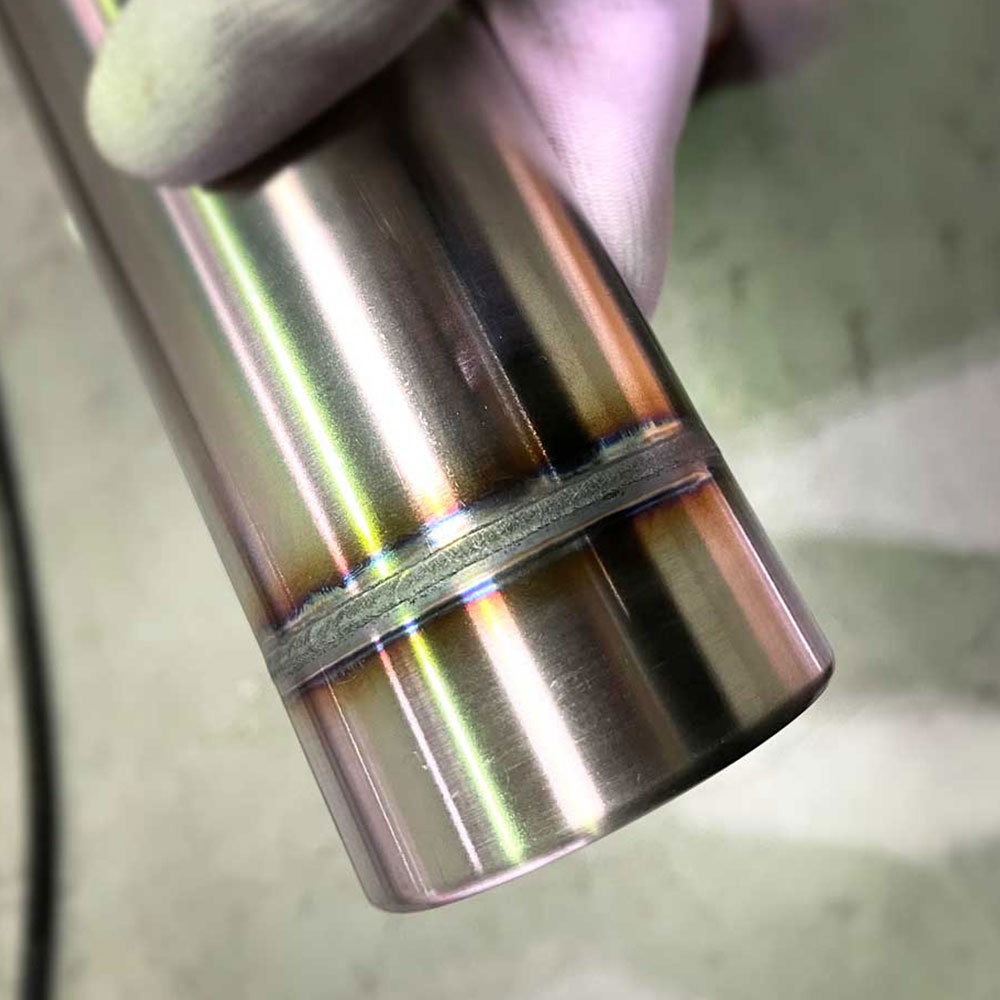

Outside of butt weld

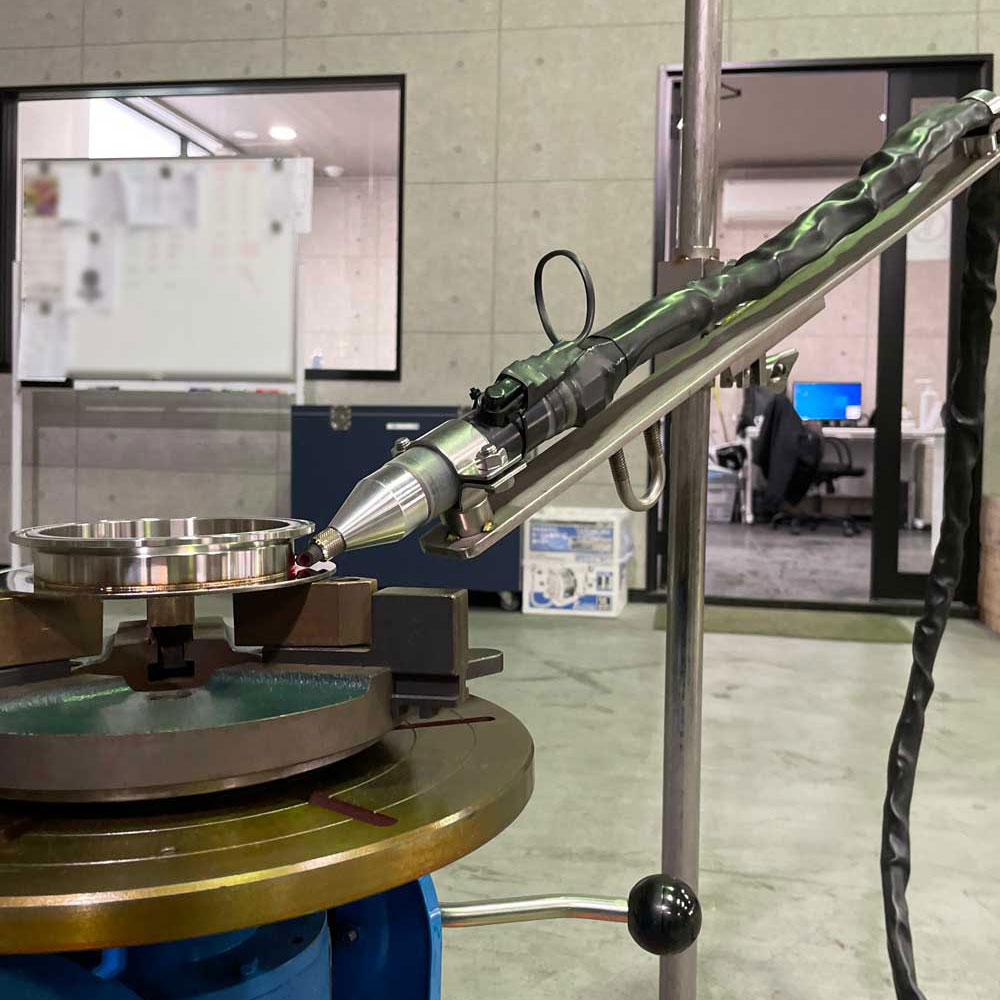

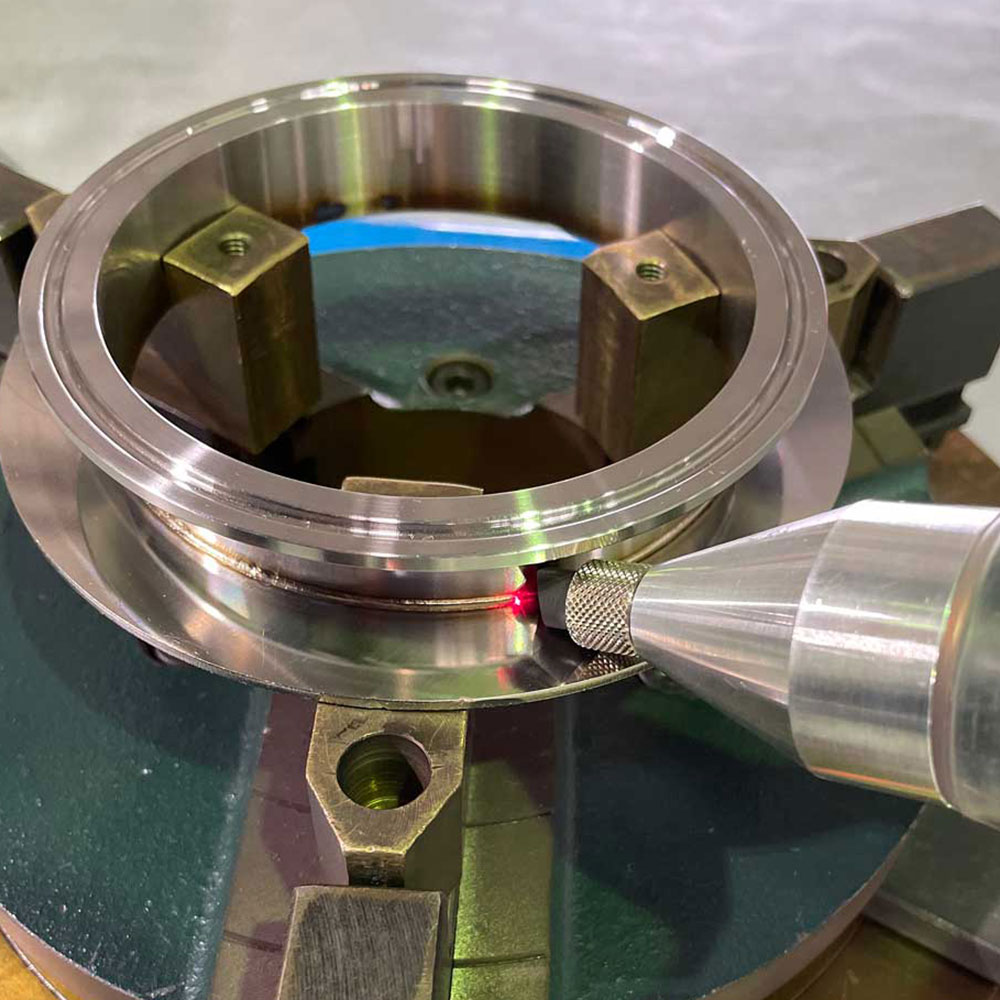

Jig with fixed arm of turntable and welding head

Such cylindrical fiber laser welding is performed by preparing a special jig.

The processing team for sanitary products is increasing the processing variation, and fiber laser welding is growing to be a new pillar of piping and utility production.