Inner surface of long pipe: Honing processing & electropolishing finish (workable for 24.5mm ~ 150A diameter pipe)

We provide inner surface honing processing & electropolishing services for stainless steel 4m-pipe* with diameter of 25.4 mm to 165.2 mm (150 A). The finished products can be used not only for process lines that require high cleanliness, but also for precision equipment such as electron microscope cylinders.

*Honing processing and electropolishing (EP) are applied for 4m pipes.

[Photo 1] From the left, the raw tube, after honing processing (intermediate process), product (honing processing + electrolytic polishing)

Overview of honing processing

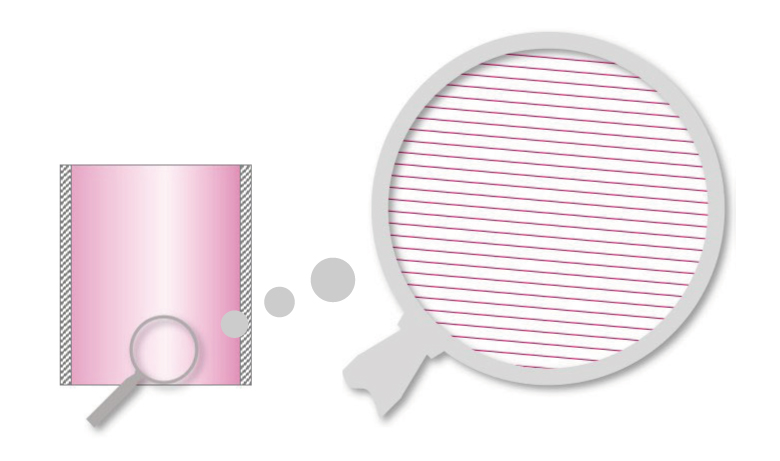

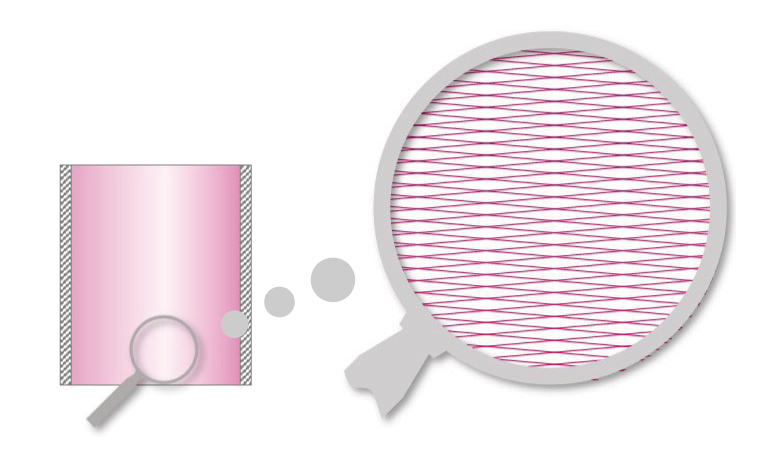

The surface after polishing becomes more subdivided uneven in honing processing than in normal polishing [see Fig. 1]. This works effectively to remove contaminants and dissolve layers with unstable composition and structure when the inner surface of the pipe is electropolished (EP), and enhances the cleaning of the inside of the pipe by electropolishing.

FIG. 1 is a polishing image of normal polishing (left) and honing processing (right).

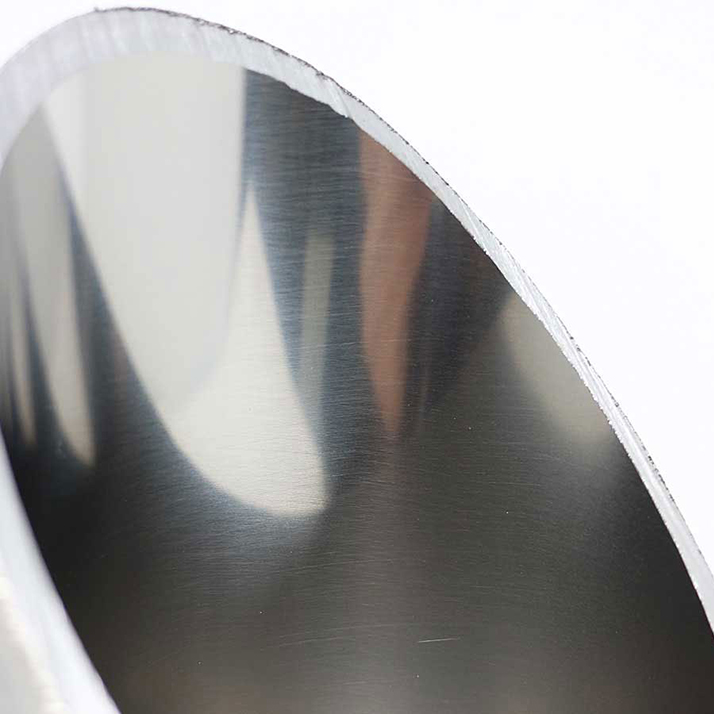

The below picture shows the inner surface of good that had been through honing processing before electropolishing.

[Photo 2] Work-in-process good before electropolishing (cloth-polished)

“Honing processing + electropolishing” finish by electropolishing a cloth-polished pipe ↓ is as follows.

[Photo 3] Honing processing + electropolishing finish

Product Specifications

Product: Honing processing of long pipe + electropolishing finish

Diameter: 25.4mm-165.2mm (150A)

Length: 4000mm (standard size only)

* We do not sell work-in-process products that have only been cloth-polished.

* The pipe length for honing processing + electropolishing specifications is 4000 mm per pipe. Only standard size is sold.