Back shield management of stainless steel sanitary pipe welding

Strict protection of the inner-side of the welded metal object with inert gas

In stainless steel pipe welding, TIG welding is generally used to prevent oxidation of the weld. However, improper TIG welding may cause problems when oxygen is mixed in when forming a weld bead on the inner side of the tube from the outer side.

In particular, if the oxygen concentration inside the tube to be welded is inappropriate, defects such as oxidation of the back bead, poor shape, and linear defects in the bead notch will occur. In some cases, corrosion may occur at unexpected times during usage, leading to serious problems.

Preparation for manual welding (shield for welding gas)

Shielding gas is injected into the pipe and the internal pressure is checked before welding.

Nissho Astec sets up a standard value for the oxygen concentration inside the shielded atmosphere based on the application and specifications of the stainless steel (or titanium, etc.) product and/or the agreement with the customer. Precise piping products are formed through accurate measurement with an oximeter, installation of an appropriate back shield jig, and operation of a welding machine to form a flawless welding bead without oxidization.

Head type automatic welding

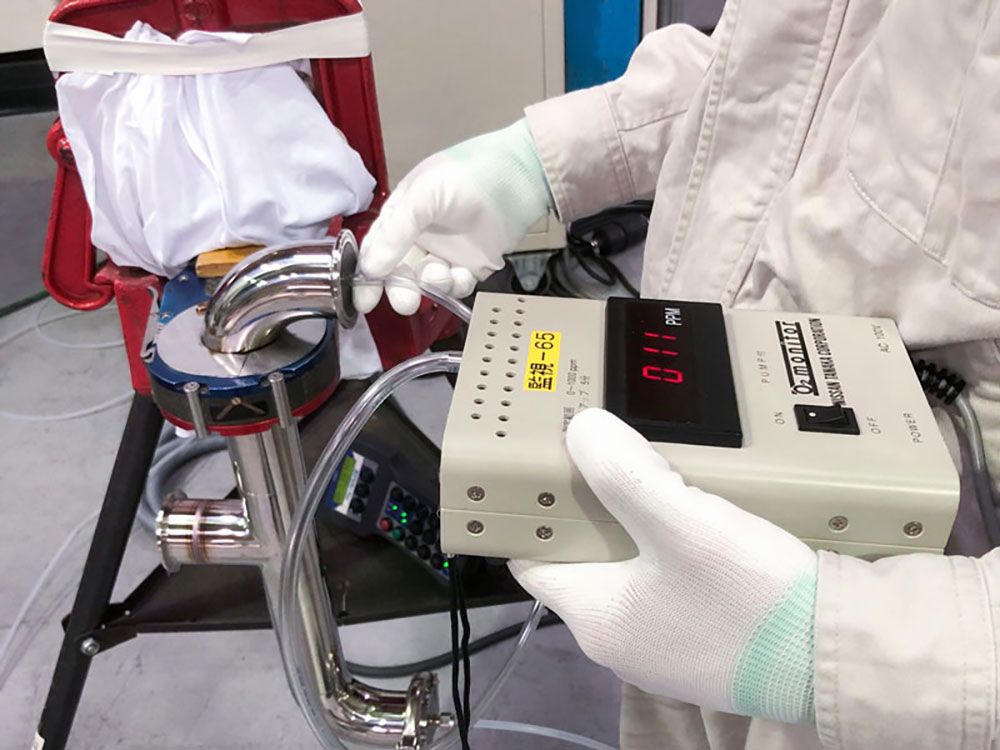

Measurement of residual oxygen concentration of work with O2 monitor

Welded pipes with an oxygen concentration of less than 30PPM

Glossary

Shielding gas:

Inert gas is flowed around the arc during welding to shut off molten metal and air. The gas does not react with oxygen (O2) and nitrogen (N2), which are air components. This gas is called Shielding gas.

When arc welding is performed without using shielding gas, defects in the performance, appearance and shape of the weld metal occur. In general, an inert gas such as argon (Ar) or helium (He) is used as a shielding gas for welding stainless steel, aluminum (Al), titanium (Ti), etc,..

TIG Welding:

GTAW(Gas Tungsten Arc Welding)

References: Wikipedia “TIG Welding” Japan Welding Association “WE-COM Magazine 2015.7 No17”